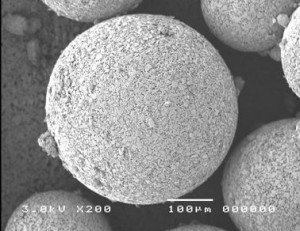

Freeze Granulation is today beeing used for commercial mixing, granulation and drying of different abrasive products. The resulting products have a homogeneous distribution of all active material, like superabrasive particles, resulting in improved milling performance and long tool life.

—

Please contact us and we will further discuss the opportunities with Freeze Granulation on your powder system and read more on technology and we propose a Granulation Test of your powder system.