Freeze Granulation – homogeneous wet granulation of powders

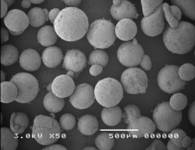

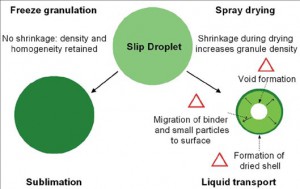

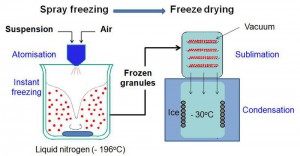

Freeze Granulation is a wet granulation method where the powders, chemicals and binders are first mixed and dispersed in a solvent. In the next step the homogeneous slurry is pumped and sprayed through a nozzle to form droplets, which are sprayed into liquid nitrogen for instant freezing. In the final step the frozen granulate is moved to a freeze dryer where the solvent is sublimated leaving spherical, dust-free and homogeneous granules. The solvent could be water or organic solvents with a freezing point close to zero degree, like cyclohexane.

Please contact us for more information and a test-granulation of your powder system.