Typical applications for Freeze Granulation are homogeneous granulation and drying of engineering (advanced, fine, high-performance) ceramic powders; oxides (alumina (Al2O3), zirconia (ZrO2), silica (SiO2)), nitrides (silicon nitride (Si3N4)) and carbides (SiC) and also granulation of powders of metal oxides, plasma spraying, nanomaterials (nanopowders), diamonds (PCD/CBN inserts), LED Lighting, pyrotechnicals (igniters, delay elements) and drying of pharmaceuticals and drugs, and for drying of biomaterials like proteins, enzymes and fine chemicals.

News

Pressing of powders

Pressing is the dominating shaping technique for ceramics and powder metals. Submicron and/or composite powders require adequate preparation to achieve a pressing performance that ensures dense compaction into a homogeneous state.

Conventional powder granulation methods (spray drying, sieve granulation etc) show drawbacks. Migration phenomena cause inhomogeneities and hard granules that do not disintegrate properly during pressing.

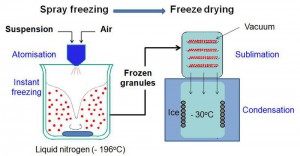

The preparation of a powder suspension by applying colloidal processing combined with sufficient mechanical treatment provides optimal homogeneity

- can be preserved by spray freezing and subsequent freeze drying resulting in

Homogeneous powder granules with superior performance made by Freeze Granulation.

—-

Please contact us and we will further discuss the opportunities with Freeze Granulation on your powder system and read more on technology and we propose a Granulation Test of your powder system.

Nanoparticles processing

Processing of nanoparticles using Freeze Granulation, Spray Freeze Drying, you will get optimal properties of your nanoparticles when mixing them with other powders or materials. The homogeneity of the powder mixture will be kept throughout the process steps, in spraying, freezing and drying, resulting in a dry granulate with homogeneously distributed nanoparticles.

Plasma spraying

Freeze Granulation is today being used to process plasma spraying powders for to achieve a homogeneous mixture and spherical granules for improved thermal spraying performance.

—

Please contact us and we will further discuss the opportunities with Freeze Granulation on your powder system and read more on technology and we propose a Granulation Test of your powder system.

Thermally sensitive nanoparticles

By using Freeze Granulation, spray freeze drying (SFD), you can produce dry-powder aggregates of thermally sensitive nanoparticles. Dry powder inhaler (DPI) delivery of therapeutic nanoparticles requires the nanoparticles to be transformed into inhalable micro-scale aggregate structures (i.e. nano-aggregates). With Freeze Granulation you will be able to optimize the aerosolization efficiency of the nano-aggregates, while keeping the morphology, production yield, flowability, and aqueous reconstitution in the desirable range.

Needle-free ballistic powder delivery

By applying Freeze Granulation you will be able to make microparticles with high insulin loading (nanosuspension) suitable for needle-free ballistic drug delivery. The resulting granules are homogeneous and robust with a diameter of around 50-150 µm, with a narrow size distribution and a high content of insulin.

Protein aerosol powders

Freeze granulation, as opposed to spray drying, has been shown to produce protein particles with light and porous characteristics, which offered powders with superior aerosol performance due to favorable aerodynamic properties, suitable granulation technology for protein inhalation powders.

Frysgranulering för tillverkning av homogena granuler (in Swedish)

LED photoluminescence granulation

Freeze Granulation is today used for commercial production of homogeneous granules for the production of oxides used as a ceramic phosphor plate for white illumination in LED Lighting. By using Freeze Granulation of the powder and binder mixture, compared with spray drying, it is possible to manufacture a homogeneous phosphor plate with optimal properties for to generate a soft and warm white light from high power LEDs.

Ultrasonic atomisation

Freeze Granulation can be made using ultrasonic atomisation of the droplets. The resulting granules have a narrow granule size distribution and the granule size is in general smaller (average 120 micron) compared to a regular spray nozzle. The granulation speed is also slow with about 0.3 to 0.5 litre/h.