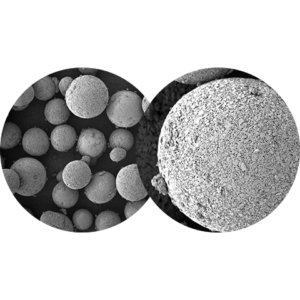

The way to optimize powder processing

We develop, manufacture, market and sell equipment for Freeze Granulation

Lab-scale Granulator

We provide three different lab-scale units for freeze granulation; LS-2, LS-6 and LS-6nms.

Freeze dryer

Compact table top freeze dryer for effective lyophilization with wireless shelf technology.

Granulation test

Want to try for yourself? We provide Granulation Tests and start-up at site.