ECerS XIII Conference – Limoges, France – Welcome to PowderPro’s stand No 1 at the exhibition at ECerS XIII Conference (European Ceramic Society) in Limoges, France from the 23rd to the 27th of June 2013. We look forward to meet customers, partners and new contacts for interesting discussions in our stand!

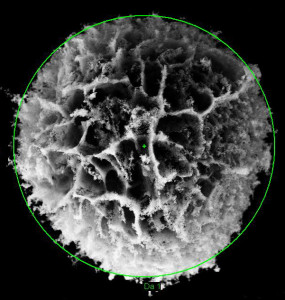

We plan to have our equipment available at a nearby lab for you to see the process of Freeze Granulation.

Please contact us and we will further discuss the opportunities with Freeze Granulation in your powder system and read more on technology and a Granulation Test of your powder system.