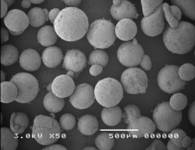

Freeze Granulation is today being used by market leaders in manufacturing of diamond tools like diamond wheels using PCD – Polycrystalline Diamonds. Homogeneous distribution of the active component, diamond particles, in diamond wheels is very important for the cutting performance and tool life. By using Freeze Granulation you will bring your slurry, with diamonds, in the powder-mixture/dispersion to homogenous granules of diamond particles with inorganic fillers and binders, which results in improved cutting performance and tool life in the pressed and sintered advanced diamond composite product.

The granules should only be sufficiently big. As we get the diamonds homogenously distributed in suspension they will be homogeneously distributed in the granules. The risk to get agglomerated diamonds is bigger if you add diamonds after the granulation step.