Spray-freezing and freeze drying – Freeze Granulation

PowderPro AB develop, manufacture, market and sell equipment and know-how for Freeze Granulation, spray freezing and subsequent freeze drying (lyophilization or cryodesiccation). Freeze Granulation was developed in late 1980s at Swedish Ceramic Institute in Göteborg and it is also a development of Spray Freeze Drying (SFD) and Spray Freezing into Liquid (SFL).

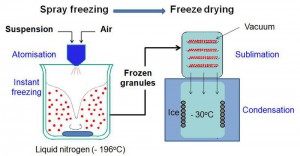

Spray cooling or rather called spray freezing is the first step in the freeze granulation process where a suspension is atomized, sprayed with a nozzle, into a chamber with liquid nitrogen. The small droplets are then rapidly frozen with a minimum of ice crystal growth. The frozen material (granules) are then transferred to a freeze dryer where the ice is removed by sublimation, i e never go through a liquid state that ensure homogeneity preservation.

Below you can see an illustration of the Freeze Granulation process.

Please contact us for more information and a test-granulation of your powder system.