Pros and cons

Colloidal approach for pressing

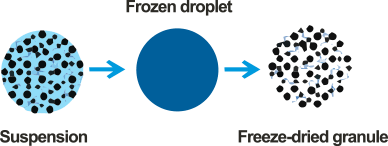

Idea to lock and transfer suspension homogeneity into granules

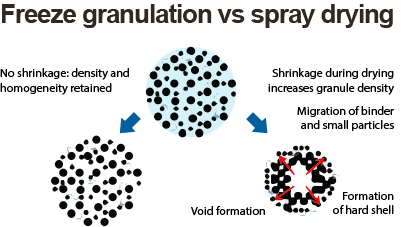

Advantage of Freeze Granulation compared with Spray Drying

- The granule density can be controlled (solid content of the slip)

- No cavities (voids) in the granules

- No migration of small particles and/or binder gives a high degree of granule homogeneity

- Nanopowders and enzymes can be granulated and dried into a powder and then re-dispersed to nanopowders again avoiding agglomeration (aggregates) of nanoparticles, which is not possible with other granulation methods like spray drying

- Low temperature granulation and drying of pharmaceuticals, drugs, biomaterials and fine chemicals, quick and easy to redispers

- A mild drying procedure minimises oxidation of non-oxides and metals

- Lower granule density and evenly distributed pressing aids gives softer granules and ensure that all granules are broken during compaction

- Low waste of material (high yield)

- Not only large quantities but also very small experimental batches 50–100 ml slip) can easily be processed

- The equipment is easy to clean (allows the use of latex as binder)

- Possibility of recycling organic solvents

Disadvantages of Freeze Granulation compared with Spray Drying

- Two process steps: spray freezing and freeze drying

- Limitation in the choice of solvent, based on the freezing properties – a freezing point between –20 and +10 °C is recommended (water and cyclohexane)

- Large-scale equipment with a capacity beyond 100 kg granules per day needs to be further developed